A crushed rock driveway offers exactly what Denver gardens need: a permeable surface that manages stormwater, withstands freeze-thaw cycles better, and creates visual harmony with the native rock and plants that thrive in our semi-arid climate.

In this guide, you’ll discover everything you need to know about crushed rock driveways.

We’ll explore:

- What makes crushed rock different from ordinary gravel

- Which rock types deliver the best performance in our zone 5b-6a climate

- Realistic costs

- Detailed installation steps.

Let’s find out now!

What is a crushed rock driveway vs gravel?

The terms sound interchangeable, but the distinction matters for driveway performance.

- Crushed rock comes from stone quarried and processed through mechanical crushers. The crushing process creates angular, irregular pieces with flat faces and sharp edges. Think of breaking a plate – you get pieces with distinct angles and flat surfaces.

- Gravel forms naturally through erosion and weathering. You find gravel in streambeds and ancient riverbeds. Those rounded edges look attractive in garden beds, but they create problems in driveways.

Angular crushed rock delivers better driveway performance through simple physics. The flat faces and sharp edges lock together when compacted.

Each piece wedges against its neighbors, creating a stable matrix that resists shifting under vehicle weight. Rounded gravel pieces roll and slide past each other. They never develop the same interlocking strength.

Types of crushed rock for driveways

Building a crushed rock driveway requires layering different rock sizes. The base layer uses larger, more angular material for structure. The surface layer needs smaller pieces that are compact and smooth for driving.

Base layer

Crusher run (crush-and-run)

Crusher run blends crushed stone with fine particles called stone dust or screenings. When you compact this mixture, the fines fill gaps between larger rock pieces, creating a stable base. The material packs hard enough to support heavy vehicles while remaining permeable enough to drain water.

Crushed rock #3 and #4

These designations refer to rock sizes between 1.5 and 2.5 inches. Number 3 crushed rock measures roughly 1.5 to 2 inches. Number 4 runs 1 to 1.5 inches. Both work as base layers for heavy-duty applications or as a sub-base under crusher run on long driveways.

You might use #3 or #4 rock when installing a driveway that will see RV traffic or construction equipment. The larger pieces create a more open structure than crusher run alone, improving drainage in areas where water movement is critical.

Surface layer

Crushed stone #57

This three-quarter-inch crushed rock creates excellent driveway surfaces. The uniform size allows for good compaction while maintaining enough space between particles for water drainage.

The angular nature of #57 stone means it locks together well, resisting the ruts and displacement that plague smooth gravel.

In Denver, #57 stone works particularly well for driveways that won’t see constant heavy traffic. It provides a clean, attractive surface that complements rock gardens and xeriscape designs.

Crushed stone #411

Think of #411 as #57’s more compact cousin. This blend combines three-quarter-inch crushed rock with stone dust.

When compacted, the dust fills voids between larger pieces, creating a firmer, smoother surface than #57 alone. The trade-off comes in permeability – #411 drains slightly slower than pure #57 but provides better snow removal and a more finished appearance.

Crushed decomposed granite (DG)

Decomposed granite offers a fine-textured, natural-looking surface that compacts very hard. When properly installed with stabilizers, DG creates a surface that almost feels like packed dirt but drains like gravel. Colors range from gold to tan to reddish brown, depending on the granite source.

Denver’s freeze-thaw cycles present challenges for DG surfaces. Pure DG can heave and crack during winter. Some installers add stabilizing polymers to improve cold-weather performance.

The dust factor also deserves consideration. DG creates more dust than coarser crushed rock during dry, windy summers. Plan on occasional watering to keep dust down if you choose this option.

Crushed rock driveway pros and cons

Every driveway material involves trade-offs. Understanding what crushed rock driveways do well and where they fall short helps you make a decision that fits your property and lifestyle.

Advantages

Permeable surface reduces runoff

Water soaks through crushed rock instead of running off into storm drains. This matters in Denver where water conservation drives many landscape decisions. A permeable driveway acts like a rain garden, allowing precipitation to recharge groundwater rather than contributing to stormwater runoff.

Permeable surfaces filter pollutants from runoff and reduce the urban heat island effect that makes cities hotter than surrounding areas. Your driveway becomes part of your water management strategy instead of working against it.

Cost-effective for long or wide driveways

Concrete costs climb rapidly as driveway dimensions increase. A 20-foot by 50-foot concrete driveway might run $8,000-$12,000 installed. The same dimensions in crushed rock typically cost $2,500-$4,500, including professional installation. For rural properties with longer driveways, the savings multiply.

Easier DIY installation than concrete or pavers

Pouring concrete demands precision, special tools, and good weather. Mistakes become permanent. Crushed rock installation is more forgiving. You work in layers, compacting as you go. If a section doesn’t turn out right, you can rake it out and redo it. The process breaks down into manageable weekend projects.

Homeowners with basic DIY skills can install a crushed rock driveway using rented equipment. The learning curve is gentle compared to concrete work. Many Denver homeowners tackle their own driveways, hiring contractors only for excavation or equipment operation.

Disadvantages

Requires periodic maintenance

Crushed rock driveways need raking to stay level and attractive. High-traffic areas develop ruts over time. Edges require redefining. Most driveways need a fresh layer of surface rock every 3-5 years to maintain appearance and function. Plan on adding a half-ton to a ton of rock every few years depending on driveway size.

Snow removal challenges

Shoveling or plowing crushed rock driveways requires technique. Dig too deep and you scrape up rock along with snow. Set your snow blower too low and you’ll spray rock across your lawn. Most homeowners learn to raise their blades and work carefully.

Using a slightly larger surface rock (#57 instead of #411) makes it easier to see and avoid during snow removal.

Dust on sunny, windy days

Driveways with stone dust in the mix kick up dust when dry. The dust settles on nearby plants and finds its way into garages.

Occasional watering reduces dust, but that works against water conservation goals. Choosing a surface layer with less fine material (pure #57 instead of #411) cuts dust at the cost of slightly rougher texture.

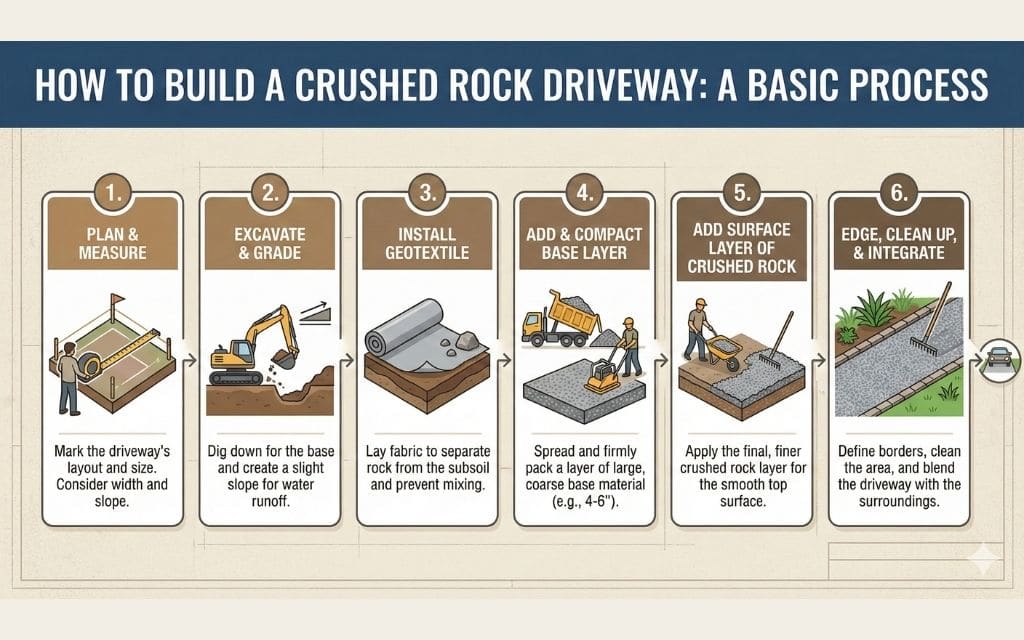

How to build a crushed rock driveway in Denver (Step-by-Step)

Installing a crushed rock driveway follows a logical sequence. Rushing steps or skipping preparation leads to problems. Take time to do each phase right and the driveway will perform for decades.

Step 1: Plan and measure

Walk the route from the street to the garage. Mark the edges with spray paint or stakes and string. Measure length and width at several points – driveways rarely run perfectly parallel. Add a few inches to width measurements to account for edge containment.

Calculate square footage by multiplying average length by average width. For rock quantity, you need to know depth. A typical crushed rock driveway uses 4-6 inches of base layer and 2-3 inches of surface layer. Here’s the formula:

Square footage × depth in feet ÷ 27 = cubic yards needed

For a 12-foot by 40-foot driveway with 4 inches of base (0.33 feet) and 3 inches of surface (0.25 feet):

- Base: 480 sq ft × 0.33 ft ÷ 27 = 5.9 cubic yards

- Surface: 480 sq ft × 0.25 ft ÷ 27 = 4.4 cubic yards

Round up and add 10% for compaction and waste. Order 7 yards of crusher run and 5 yards of #57 or #411.

Step 2: Excavate and grade

Remove grass, weeds, and topsoil to reach a stable subgrade. In Denver’s clay soils, you might dig down 6-8 inches total to accommodate base and surface layers without raising the final grade too much above surrounding areas.

Shape the excavated area with a slight crown – the center sits 1-2 inches higher than the edges. This crown sheds water toward the sides where it can drain into landscape beds or toward the street. Without proper drainage, water pools on the surface or undermines the base.

Use a laser level or a long straight board with a level on top to check your crown. Small adjustments at this stage prevent water problems later. Compact the exposed subgrade with a plate compactor if the soil is loose or disturbed.

Step 3: Install geotextile (optional but recommended)

Geotextile fabric separates crushed rock from soil. Without this barrier, clay gradually migrates up into the rock base. The rock settles down into the clay. Over years, this mixing weakens the driveway and creates muddy spots.

Roll geotextile across the excavated area, overlapping edges by 6-12 inches. Secure it temporarily with landscape staples or rocks. The fabric should extend slightly beyond the driveway edges to prevent soil infiltration from the sides.

Choose a non-woven geotextile rated for driveway use. The label should indicate it’s designed for separation and stabilization, not just erosion control. Heavier fabrics last longer and provide better performance under the repeated loading of vehicle traffic.

Step 4: Add and compact base layer

Spread crusher run or your chosen base rock in lifts no more than 3-4 inches thick. Run a plate compactor over the entire surface in overlapping passes. Listen for changes in sound—the pitch rises as material compacts.

Make 3-4 passes over each area. Add water lightly if dust prevents good compaction, but avoid creating mud. After compacting the first lift, spread the second lift and repeat. Continue until you reach the planned base depth.

The surface should feel rock-hard under foot. If you can easily push a screwdriver into the compacted base, you need more compaction.

Step 5: Add surface layer of crushed rock

Spread your chosen surface material (#57, #411, or other) to the planned depth. Work from one end toward the other to avoid driving on uncompacted material. Rake the surface level, maintaining the crown you established during grading.

Compact the surface layer using the same multiple-pass technique as the base. The surface should feel firm but not quite as hard as the base layer. Some give in the top layer is normal and actually improves the driving feel.

Check the final surface with your straight edge and level. Make sure water will drain to the sides. Fill any low spots and recompact.

Step 6: Edge, clean up, and integrate with landscaping

Install edge restraint to keep crushed rock contained. Options include:

- Steel edging (durable, clean lines, higher cost)

- Plastic edging (economical, less visible, adequate for most driveways)

- Timber edging (natural look, requires replacement every 5-10 years)

- Boulder edging (blends with xeriscape, most expensive)

Rake the final surface smooth and remove loose rock from surrounding areas. Where the driveway meets walkways or garden beds, create clean transitions. Match the driveway rock to landscape rock where possible. Use complementary colors where you want contrast.

Consider how the driveway interacts with your existing xeriscape. The crushed rock should feel like an intentional part of the design, not an afterthought. Extend similar rock into bordering beds. Echo the driveway’s color in pathway edging or decorative boulders.

How much does a crushed rock driveway cost?

Understanding costs helps you plan accurately and avoid budget surprises. Crushed rock driveway expenses break down into materials, equipment, labor, and site-specific factors.

Material cost ranges

Crushed rock prices in the Denver area vary by rock type and order quantity. Here’s what you can expect per ton delivered:

| Material Type | Cost Per Ton | Typical Use |

| Crusher run (base) | $30 – $45 | Base layer for all driveways |

| Crushed rock #3/#4 | $35 – $50 | Heavy-duty base or sub-base |

| Crushed stone #57 | $35 – $55 | Surface layer, good drainage |

| Crushed stone #411 | $40 – $60 | Surface layer, firm finish |

| Decomposed granite | $45 – $75 | Specialty surface, decorative |

| Crushed limestone | $50 – $80 | Specialty option, light color |

| Recycled concrete | $25 – $35 | Budget base or surface |

Factors that change the price

Driveway length and width

Longer and wider driveways cost more, but the per-square-foot price often drops. A 20-foot by 100-foot driveway (2,000 square feet) might run $1.00-$1.50 per square foot installed instead of $1.50-$2.00 for a smaller driveway. Contractors can work more efficiently on larger projects. Rock suppliers offer better rates on bigger orders.

Rock type selection

Standard crushed rock from local quarries costs least. Specialty materials like crushed limestone or high-grade decomposed granite can double material costs. Recycled crushed concrete offers savings, often 20-30% less than quarried rock.

Access and site conditions

Steep slopes require more excavation and better drainage planning. Narrow alleys or limited access may prevent delivery trucks from reaching your property, forcing wheelbarrow work or small loads. Removing old concrete or asphalt before installing crushed rock adds $2-$5 per square foot to total costs.

Geographic location

Properties in Littleton or Lakewood with nearby quarries pay less for delivery than homes in remote mountain areas. Denver Metro enjoys competitive pricing because multiple suppliers serve the region. Heading into the mountains or out to the plains increases delivery charges.

Maintenance tips for long-lasting crushed rock driveways

Proper maintenance keeps a crushed rock driveway attractive and functional for decades. The work is straightforward but does require regular attention.

Proper maintenance keeps a crushed rock driveway attractive and functional for decades. The work is straightforward and requires regular attention.

Routine care

Raking and leveling

- Walk your driveway monthly during heavy-use seasons to spot ruts and low areas

- Use a heavy landscape rake to pull rock from high spots into depressions

- Compact problem areas with a hand tamper after raking

- Rent a plate compactor annually to re-compact the entire surface

- Plan 15 minutes per session for routine leveling

Topping up rock

- Add fresh surface rock every 2-4 years depending on traffic volume

- Order half-ton to one ton of surface material for average driveways

- Spread evenly and compact into place

- Schedule topping up for late spring after freeze-thaw cycles end

- Water slightly during compaction to improve settling without creating mud

Keeping drainage clear

- Check driveway edges several times yearly for debris buildup

- Rake out leaves, pine needles, and windblown material blocking water flow

- Clear culverts and drainage swales before spring runoff

- Inspect drainage channels after heavy storms

- Ensure water flows freely off edges into landscape beds

Snow and ice management

Best tools and techniques

- Set snow blower 2-3 inches higher than normal to avoid rock displacement

- Use plastic shovels instead of metal—they glide without catching rock edges

- Push snow rather than scoop to keep blade angle shallow

- Make multiple light passes instead of one deep pass

- Accept leaving thin snow layer to protect rock surface

Ice control methods

- Skip salt – it damages nearby plants and increases soil salinity

- Use sand or fine gravel for traction on icy patches

- Keep bucket of surface rock to spread on ice (disappears when ice melts)

- Avoid chemical deicers that harm Denver’s already alkaline soils

Managing migrated rock

- Walk driveway edges each spring with a bucket

- Pick up visible rock pieces from lawn and beds

- Use lawn rake before first mowing to collect smaller pieces

- Budget 1-2 hours for spring rock recovery

- Return collected rock to driveway surface

[Maintenance tips for long-lasting crushed rock driveways]

Conclusion

Crushed rock driveways deliver natural beauty that complements xeriscape beds and rock gardens. The materials are straightforward – angular stone in compacted layers. Installation follows clear steps that experienced DIYers can handle. Costs stay reasonable compared to concrete or asphalt. With basic maintenance, the results last decades.

____________

For nearly two decades, Mile High Lifescape has transformed Denver Metro driveways and landscapes. Whether you need guidance on landscape rock selection, help with site challenges, or full installation services, our team brings experience with everything from small residential driveways to large-scale projects.

Call (303) 877-9091 or email hello@milehighlifescape.com to discuss your driveway transformation.

Frequently asked questions (FAQs)

Are crushed rock driveways good for Denver’s climate?

Yes. Crushed rock handles Denver’s freeze-thaw cycles better than concrete or asphalt. The permeable surface drains water instead of pooling and freezing. When ground movement occurs, simply add rock and recompact settled areas. Concrete cracks under the same conditions and requires expensive replacement. The flexibility makes crushed rock ideal for our temperature extremes and clay soils.

What type of crushed stone for driveway bases works best in Denver?

Crusher run delivers best performance for most Denver bases. This blend of crushed rock and fine particles compacts hard while remaining permeable. It handles clay soil expansion and contraction without failing. For heavy-duty applications, use 4 inches of #4 crushed rock under 4 inches of crusher run for exceptional stability.

How thick should a crushed gravel driveway be?

Plan for 4-6 inches of base layer and 2-3 inches of surface layer. This handles passenger vehicles and light trucks. Driveways carrying heavier vehicles need deeper bases up to 8 inches. Proper depth prevents ruts and extends driveway life.

Can I install a crushed rock driveway myself, or should I hire a contractor?

Homeowners with basic DIY skills can install crushed rock driveways using rented equipment. The process breaks into manageable steps. However, hire professionals for driveways with drainage challenges, steep slopes, or difficult access. Consider installing your own surface layer over a professionally prepared base to balance cost savings with structural integrity.

How do crushed rock driveways compare in cost to concrete or asphalt?

Crushed rock costs significantly less. A 12-foot by 40-foot crushed rock driveway runs $2,000-$4,000 installed. The same driveway in concrete costs $6,000-$10,000. Asphalt falls between $3,500-$6,500. However, crushed rock requires ongoing maintenance while concrete and asphalt are largely maintenance-free after installation.

Will a crusher stone driveway wash away in heavy Colorado storms?

Properly installed driveways resist washout. Crown the surface so water flows to edges. Install edge restraints to contain rock. On slopes, add checkdams to slow water flow. Most damage happens when installation skips proper grading. A well-built driveway sheds water efficiently without erosion. Address minor washouts immediately to prevent growth.